Operated by skilled personnel along with a competent workforce, our ERW Tube Division makes use of the latest in tubing technology.

Some of our in-house facilities in the division include Coil Slitting, Tube Rolling, Eddy Current Testing, and several standardized tube finishing machines.

The Tube Mills have a series of forming rolls to shape the rolled strips in tubular form followed by the welding process.

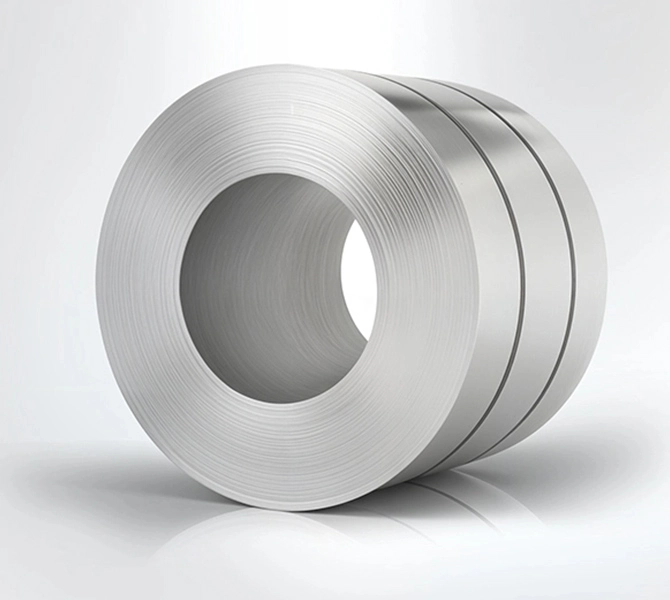

-

Uncoiler -

Shear and Welder -

Accumulation -

Sizing and Straightening -

Electric Resistance Welding -

Forming -

Cut to Length (CTL) -

ECT Machine

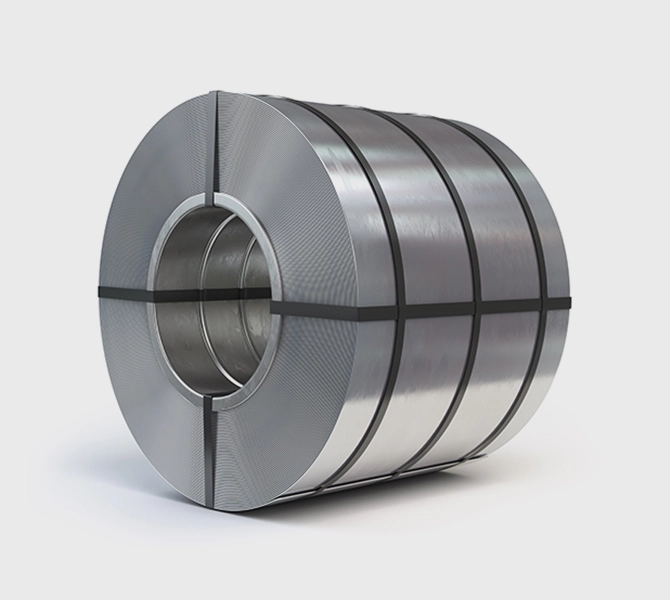

With advanced facilities and cutting-edge technology, we lead in manufacturing high-quality ERW Tubes that meet both national and international standards. Our annual capacity of 75,000 metric tons underscores our industry leadership. Operating 4 modern tube mills (1 HR Tube Mill & 3 CR Tube Mills), we produce tubes ranging from 12.70mm to 127mm in outer diameter and 0.35mm to 6mm in thickness.

Our tube mills feature a series of forming rolls for shaping rolled strips into tubular form, followed by high-frequency induction welding that ensures superior welding strength without filler material.

Quick roll changeovers maximize productivity. An online Eddy Current Tester verifies weld quality, ensuring defect-free products.

SOCO Auto Cutting and Champhering Machines precisely cut tubes into lengths from 50 to 7000 mm, providing perfect end finishing. Additional processes include external and internal bead removal, enhancing tube surface smoothness and appearance. Our Tube division offers a variety of products including Round Tubes, RHS Tubes, SHS Tubes, Oval Tubes, and D-Shape Tubes, tailored to client specifications.