We consider quality not merely a desirable attribute but an essential aspect of all our cold-rolled products.

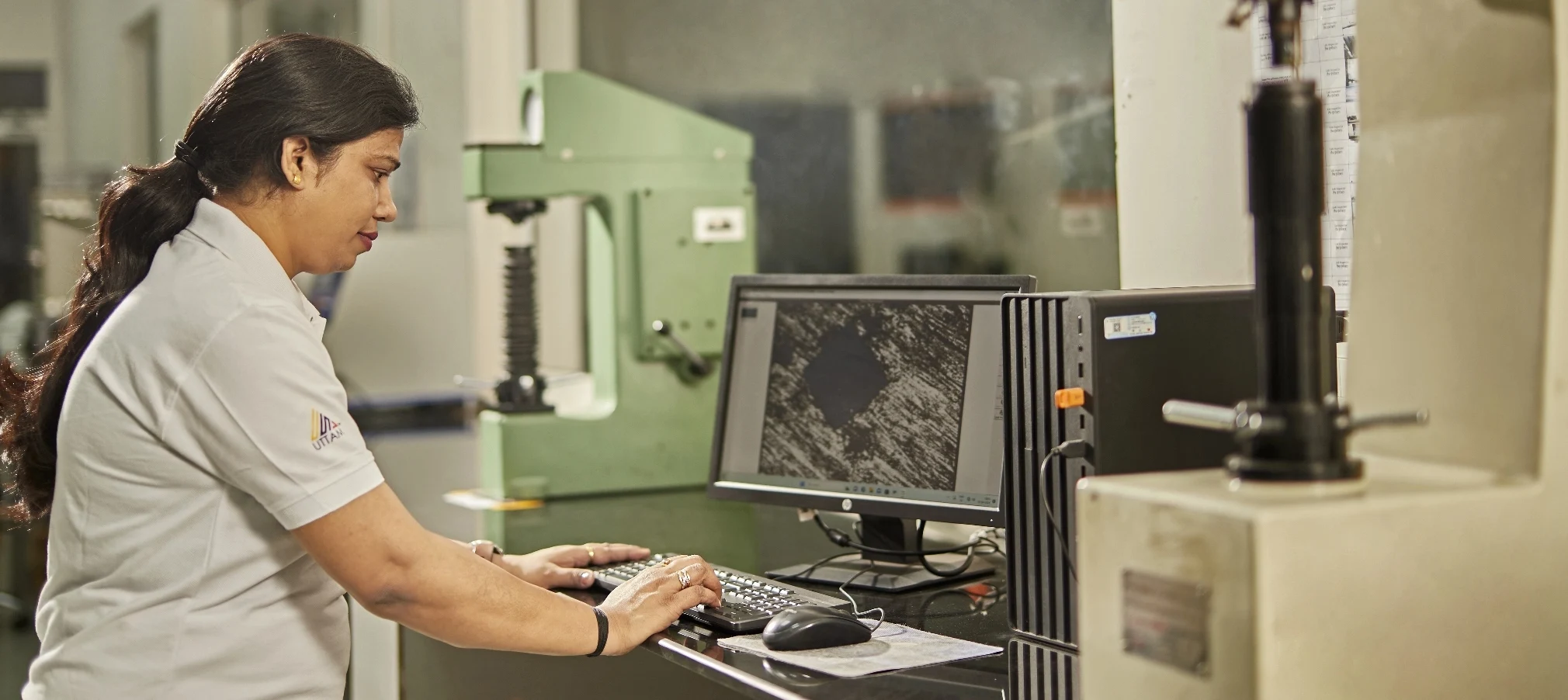

Thus, we prioritize quality throughout the manufacturing process employing a set of the latest quality inspection tools and equipment.

We have in place adequate physical inspection & chemical testing procedures starting from procurement of raw materials to manufacturing of finished product. We have a well-equipped laboratory and professional manpower to ensure the quality of our products. We also have Auto gauge control technology on the cold rolling mills & skin pass mills which gives consistent thickness across the length & width of the coil.

WE ACHIEVE OUR QUALITY GOALS BY:

- Understanding & complying with all applicable parameters

- Strengthening our quality management systems by continual improvement, and

- Learning with employee-experience, engagement and motivation.

OUR QUALITY CONTROL MEASURES DURING THE ROLLING

PROCESS ENSURE:

- Product Performance

as it impacts the products’ functionality, durability, and reliability

- Surface Finish and Appearance

for a smooth and uniform surface finish, defect-free appearance, and other surface irregularities.

- Material Properties

for strength, ductility, hardness, and surface finish

- Compliance with standards and regulations

for safety, reliability, compatibility, and market acceptance.

- Dimensional Accuracy

for precision, tight tolerances, and uniformity across batches