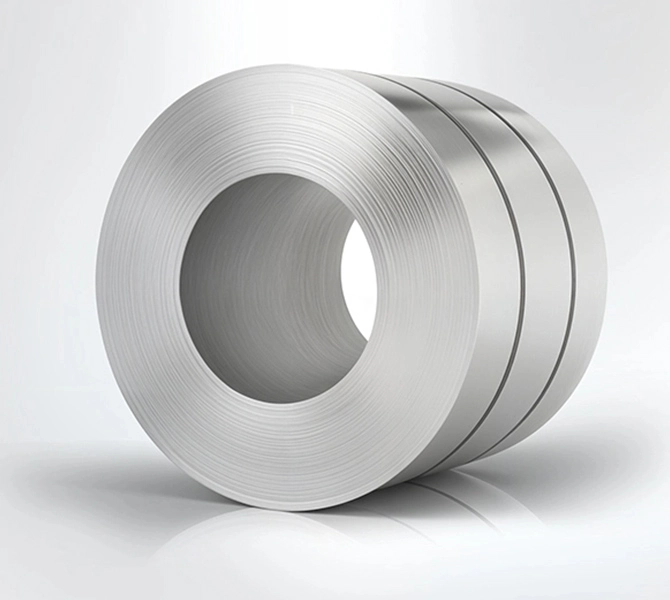

Cold Rolling Expertise: Crafting Quality Beyond Expectations

We have state-of-the-art infrastructure that enables us to manufacture the finest quality cold rolled products for diverse applications.

Equipped with the latest tools and machines, well-defined manufacturing processes, skilled workforce, and a stringent quality control system, our robust infrastructure supports us to carry out operations while meeting all the standards and specific industry requirements.

-

HR Slitter -

Pickling Line -

4-Hi Cold Rolling Mill -

4-Hi Skin Pass Mill -

Annealing Furnace -

Electrolytic Cleaning Line -

Tension Leveler Line -

CR Slitter -

Cut to Length (CTL)

Our advanced HR Slitters are capable of handling material of 1.4mm to 6mm thickness and 500-1600 mm width. The highly efficient pickling line at Uttam successfully removes harmful impurities from the surface of the metal, producing an good quality steel with highest strip cleanliness and high surface quality which is long lasting and durable. Our computer-controlled 4-Hi Reversible Cold Rolling mills make use of modern technologies like the Auto Gauge Control, Quick Roll Change Out system ensuring perfect thickness range of 0.15mm to 3.5mm.

The latest Electrolytic Cleaning Line (ECL) efficiently removes the carried-over rolling oils and iron fines left on the strip surface after rolling.

Our latest technology annealing furnaces are 100% hydrogen based, designed to carry out the complex heat treatment process smoothly, imparting the desired properties. Our cutting edge 4-Hi Skin Pass Mills provide excellent flatness, perfect finish and desired surface hardness to the CRCA products. The Tension Leveller Line stretches the material further to improve the strip shape.

The CR slitting lines precisely slit the steel coils into multiple narrow strips keeping the customers’ requirements in focus. The Cut to Length facility finally cuts the coils into desired lengths based on customer specifications.